An Introduction to Structured Cabling

Structured cabling is the planned approach to installing cable infrastructure in a building. It can also refer to the products arranged in a structured manner for that purpose. Installers need to plan the job to ensure they supply a structured cabling system to the client. A lack of planning will result in an untidy or otherwise inefficient end result.

Imagine you’re a business owner, commissioning a new build for a new office building. As your business continues to grow, you’ll be adding new devices, new access points, new staff members. You’re also making a large investment, so you need this building to last you for many years.

So, you commission a firm to come in and plan out a networking installation for your needs. This installation needs to be scalable. It also needs to be future-proofed to serve you through waves of new technology. Finally, like any effective network aspect, redundancy should be built-in. Structured cabling achieves this.

Your regular Joe might have some home networking experience. But, this experience probably didn't involve much planning. The result is known as point-to-point cabling.

Point-to-point cabling is where one device is connected to another in an ad hoc fashion. Usable in many instances, but rarely enough to meet the requirements listed above.

Structured cabling jobs can be large, involving security cameras, in-house servers, many-port network switches and more.

Structured cabling jobs can be small, as well. For example, a small business might only need the installation of a few NVR security cameras.

Factors affecting the structured cabling plan include:

- the client's requirements;

- the layout of the building;

- the existing network infrastructure.

In summary, structured cabling is the planned routing of cables, with other hardware, to meet particular requirements.

Structured Cabling Products

Here at NetXL we stock a variety of structured cabling products. Let’s take a look at the role they’ll play in a structured cabling installation.

1: The Cable - What’s best?

A structured cabling job would not be possible without some cable. In our opinion, Cat6 UTP still represents the best option for most residential and commercial applications. It’s cost-effective and supports 10Gbps data transfer for anywhere from 37m to 55m. Beyond this limit, Cat6 will supply 1Gbps transfer speeds.

We stock three flavours of Cat6 cable, plus some Cat5e, all in 305metre batches. Pictured above is our Cat6 UTP External Grade PE Cable in a 23 AWG. Confused by the name? Let’s deconstruct this:

Categories

Cat6 stands for Category 6. The higher the category number, the better the performance of the cable. The better the performance of the cable, the higher the price per metre. By ‘higher performance’, we mean:

- Higher bandwidth

- Higher max data transfer rate

Today, you will most commonly find the following categories of cable:

- Cat5e

- Cat6

- Cat6a

- Cat7

- Cat8

Cat5e can supply up to gigabit (1Gbps) speeds. For many, this will be enough. But, in the interest of future-proofing, bear in mind that Cat6 can supply 10Gbps data transfer. If you need 10Gbps transfer speeds at further than 50metres, consider Cat6a or better.

Cat6a and higher always comes shielded. The shielding is thick, making these cables heavier and less pliable than their lower category counterparts. These are sold in large, wooden spools, rather than the easy-serve boxes you see with Cat6 and Cat5e.

You will rarely need (or want) to fork out for the Cat7 or Cat8 technology. Cat7 and Cat8 are both quite new and are not yet widely used. Both support very high-speed data transfer, though this drops off over larger distances.

Cat8 is capable of 40Gbps data transfer speeds but, with 10Gbps supply speeds being a rarity, applications that can take advantage of such speeds will be few and far between.

For reference, a spool of 305m (1000ft) of Cat8 cable will set you back around £1,000.00. For data centres or hedge funds that need to be at the bleeding edge of connectivity, such investments might make sense. For all other groups, though, the cost is unjustifiable.

Though Cat5e is widely used in existing infrastructure, new installations would do better with a newer category. This will allow the site network to take advantage of faster, newer technology as and when it arrives.

Recent initiatives like the UK’s Gigabit Voucher Scheme will make 1Gbps commonplace for all. For businesses and new builds, then, it makes sense to use cable capable of supplying 10Gbps or higher in anticipation of the next step up.

Cat6 is capable of providing 10Gbps at the short-to-medium range. If you find yourself needing 10Gbps speeds at more than about 40m, it’s best to begin considering Cat6a.

Shielded/Unshielded and Foiled Twisted Pairs

The ‘UTP’ in the product name of our “Cat6 UTP External Grade PE Cable” stands for ‘Unshielded Twisted Pairs’. This refers to the wires within the cable, which are twisted together into… well, twisted wire pairs.

These ‘twisted pairs’ are then foiled (FTP), shielded (STP), or unshielded (UTP). Manufacturers can combine these methods as well. This foil or shielding either...

- Individually wraps each twisted pair (foil only).

- Wraps the entire bundle of twisted pairs (foil and/or braided shielding).

Combining these methods results in products with codes like SF/FTP. SF/FTP stands for (Shielded and Foiled with Foiled Twisted Pairs).

The shielding for the entire bundle of twisted pairs comes before the backslash. The shielding for the individual twisted pairs comes after it. So S/UTP would mean ‘Shielded (entire bundle) with Unshielded Twisted Pairs’.

What does shielding do?

Shielding and foiling protect against crosstalk (interference). This, in turn, allows for better performance. The cost per metre increases to reflect these performance enhancements.

Shielded and/or foiled bundles of twisted pairs reduce crosstalk between cables.

Foiled individual twisted pairs diminish crosstalk between the twisted pairs themselves.

Combining both approaches allows cables to reach faster data transfer speeds.

Other improvements in cable design that enable better performance include:

- Tighter twisting of twisted pairs

- An internal cross-filter, which sits between twisted-pair couplets

- Better foil and shielding combinations

An enterprise relies on its network for more than casual use. For this reason, we advise accounting for crosstalk in the structured cabling design. This could be in the way you route the cable, or in your product choice.

External Grade PE?

This part’s simple. ‘External grade’, because it is safe to run the cable outside (it’s weatherproof). Cable not listed as ‘external grade’ should only be used indoors. PE for 'polyethylene', the material the cable jacket is made out of.

CCA Cable: A Warning

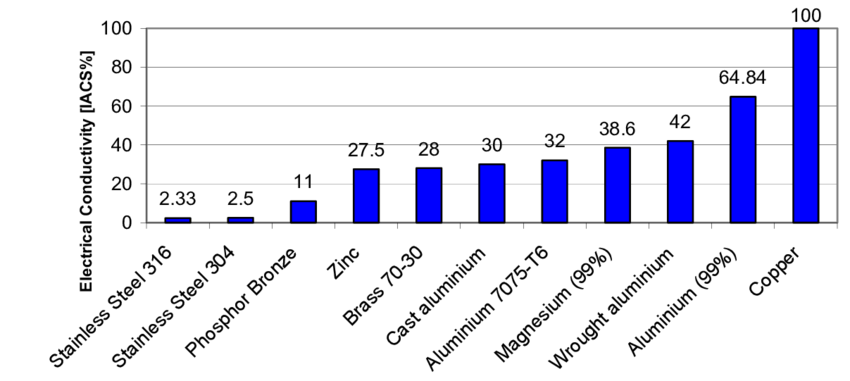

CCA stands for ‘copper-coated aluminium’. In a typical ethernet cable, the wires making up the twisted pairs consist of solid or stranded copper. Some manufacturers, though, cut their costs by substituting solid copper for copper-coated aluminium. Since aluminium is cheaper than copper, CCA cable is cheaper as well.

The issue is that aluminium is a poorer conductor than copper. The savings from substituting copper with aluminium are offset by poorer performance.

This graph shows the conductivity of various well known metals. Silver is the most conductive of all metals and sets the benchmark at 1. Aluminium and copper are side-by-side in the middle, making it easy to see how much closer copper is to the benchmark than aluminium.

23 AWG

AWG stands for American Wire Gauge. This refers to the system of the same name used to describe the thickness (gauge) of a wire. The lower the gauge, the thicker the wire.

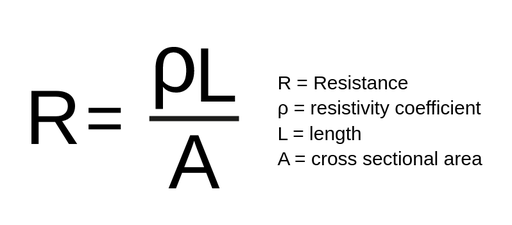

As for performance, a thicker wire (lower gauge) will yield better performance. That’s just down to science. For the physicists among you, the following equation describes resistance:

Where R is the resistance; ρ is resistivity; L is length and A is the cross-sectional area of the conductive material.

So, all else being equal, the greater the cross-sectional area of a conductor, the lower its resistance.

But why does low resistance matter for performance in an ethernet cable? Glad you asked. A higher cross-sectional area means lower resistance. Lower resistance means less heat accumulation and, therefore, less energy loss.

Since copper cable transmits data via electrical signals, loss of electrical energy as heat translates to data loss. This is why, as a rule, the lower the wire gauge, the better the cable performance.

We stock 23AWG Cat6 UTP, as well as a 24AWG Cat6 UTP cable suitable for internal applications.

Solid vs Stranded

One cable characteristic not yet discussed is solid vs stranded. This refers not to the cable, but the individual wires that make up the twisted pairs. If you were to strip the jacket off of a single wire in a twisted pair, you would see either solid copper or copper in fine strands.

Twisted pair cabling bought in bulk (in easy-serve boxes or on a spool) is solid. Solid cable is less flexible than stranded cable but retains signal better. For these reasons, solid cable is more appropriate for what is known as ‘backbone cabling’.

Backbone cabling refers to the stretches of cable that cross greater distances and carry the majority of network traffic.

By contrast, ‘patch cable’ is stranded. What the typical end-user understands an ‘ethernet cable’ to be is also stranded. This is because patch cables, as well as those for the end-user, need to be flexible. In these applications, it is not necessary for the cable to traverse any great distance. Stranded cable is appropriate, then, in those applications where shorter lengths of cable will be used and that cable should be flexible.

2: Patch Panels

Installers use patch panels to interface between incoming and outgoing connections. Incoming connections are wired into the patch panel. Patch cables then 'direct' the connection from one port to another. Usually to an outgoing connection.

Though supplied in varying lengths, patch cables tend to top out at 20metres or so. As with all cable organisation, the shortest route is best. Therefore, the best patch panel configuration will situate ports right next to each other.

Patch panels also allow for more organised cable. Remember, with structured cabling, the aim is to provide organised cable infrastructure. Organised cable is easy to maintain, reducing troubleshooting costs and network downtime.

We stock both a 24 port patch panel and a 48 port patch panel for Cat6 cable. Panels can be combined in a rack, so space is the only limitation to the number of patch panels you can use together.

3: Structured Cabling Tools and Accessories

To connect each end of the cable to an ethernet port in a wall module or patch panel, the cable first needs to be stripped. It then needs to be ‘punched in’ to the panel or module.

To cut and strip the cable, you’ll need a crimp tool like this Duratool brand 3-in-1 ratchet crimping tool. For punching the cable into a patch panel or wall module, you'll need a punchdown tool. This Excel punchdown tool for IDC and LSA blocks will serve you well. For verifying the connection through the patch panel and patch cable, you’ll need a cable tester, like this Duratool RJ45 and RJ11 cable tester. Finally, to keep everything tidy, you’ll need a nice big bundle of 100 cable ties.

4: Faceplates and Back Boxes

At the other end of the cable, it’s necessary to present the connection neatly for users and devices to use. This is where faceplates and back boxes come in. We stock both single and double gang lining back boxes for dry line walls. These are designed to be fitted flush to the plasterboard. We also stock single and double gang back boxes for solid walls, which will protrude from the wall surface.

Buy Structured Cabling Products Online

Now you know how and why you would go about a structured cabling installation for yourself or for a client. You should also have some knowledge about the products needed for various applications.

In short, the entire process is about running ethernet cable from one point to another. (Or coaxial cable, if you’re installing phone lines too). This needs to be achieved in the most efficient and intelligent manner possible.

Good planning will strike a balance between the shortest cabling route, best aesthetics and solid future-proofing. Steps should also be taken to maximise the life of the installation. For example, by avoiding locations that would expose hardware to the elements unnecessarily. This ensures a happy client and an efficient, long-lasting installation.

Choosing the right products before you start means an easier installation job. It also means better future-proofing for the arrival of new, more demanding technology.

Allowances made in the planning phase make it easy to expand the network when necessary. Minimising downtime in the event of an issue is possible with redundancy cabling.

Finally, since the cabling is well organised it is easier for the client to troubleshoot issues on their own, giving them a feeling of control and security.

All installation hardware and accessories discussed in this article can be purchased from us. If you’re a tradesman or installation business, you can sign up for a Trade account with us for special pricing.