When undertaking a network installation, using the right equipment is paramount; but when you’re weighing up the pros and cons of network switches, routers, modems, access points, point-to-point tech and a hundred other factors, it can be easy to neglect one of the most crucial decisions that can make a huge difference to how well your network runs - and that’s which cables to use.

When looking for network cables, it can be difficult to know the difference between the specifications, what they mean, and which is best for your project - puzzling out the differences between a Cat5 26AWG PVC cable and a Cat6 24AWG LSOH cable can be confusing and time-consuming, especially when an installation is working to tight margins and tighter time constraints.

That’s why we’ve put together this handy guide to walk you through your options, answer your cabling questions, and keep your network operating at peak efficiency!

So, what are the important factors to consider when looking for a cable?

Category

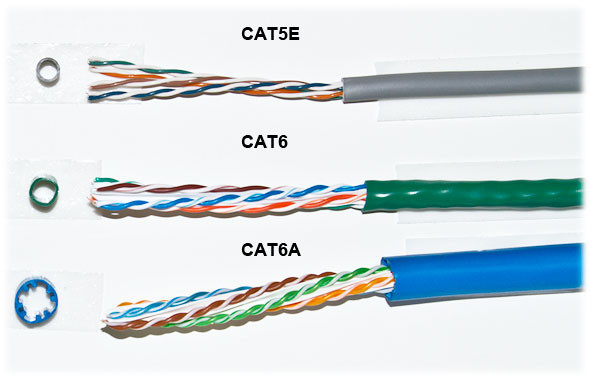

Broadly speaking, network cables can be most commonly divided into three different categories, or ‘Cats’- Cat5E, Cat6, and Cat6A.

There are actually even more categories than this - for example, Cat5, Cat7 and even Cat8 cabling - but Cat5 cables were largely decommissioned back in 2001 in favour of the higher-performance Cat5E, and Categories 7 and 8 tend to be much more specialist and designed for use in deployments like data centres and Internet Service Providers. For the vast majority of installations, you’ll be looking at Cat 5E, Cat6, or Cat6A.

In general, the higher the category, the more data that cable can transmit, and so the faster your network will perform. This is mostly related to the number of twists in the internal wires in the cable; by increasing the number of internal twists per centimetre of cable, that cable will experience less signal interference (or ‘Crosstalk’) and be able to transmit data more quickly across longer distances. Note the number of twists in each cable below - the higher the category, the greater number of twists!

Increasing the cable category also increases how much electrical signal the cable can carry without interference; this is measured in megahertz (or MHz), and cables with higher MHz ratings are generally better both at withstanding electrical interference, and transmitting data faster and over longer distances without errors.

Take a look at the table below which lays out the difference between the different cable categories:

| Cat5E | Cat6 | Cat6A | |

| Data Speed | 1 Gbps | 1 Gbps | 10 Gbps |

| Frequency (MHz) | 100 MHz | 250 MHz | 500 MHz |

You’ll notice that, while Cat5E and Cat6 cables have the same theoretical data speed, a Cat6 cable has a better MHz rating; this means that it’ll be able to transmit data more reliably, with less interference, over a greater distance.

As the category of cable increases, the price is also liable to increase. When weighing up your cable options, it’s always worth assessing the maximum data rates you’ll need - a Cat5E cable, for example, may be plenty, especially if cost is a factor in your deployment!

So as we can see, the category of cable can tell you a lot about how that cable will perform; however, it’s not the only important factor!

Conductor Type

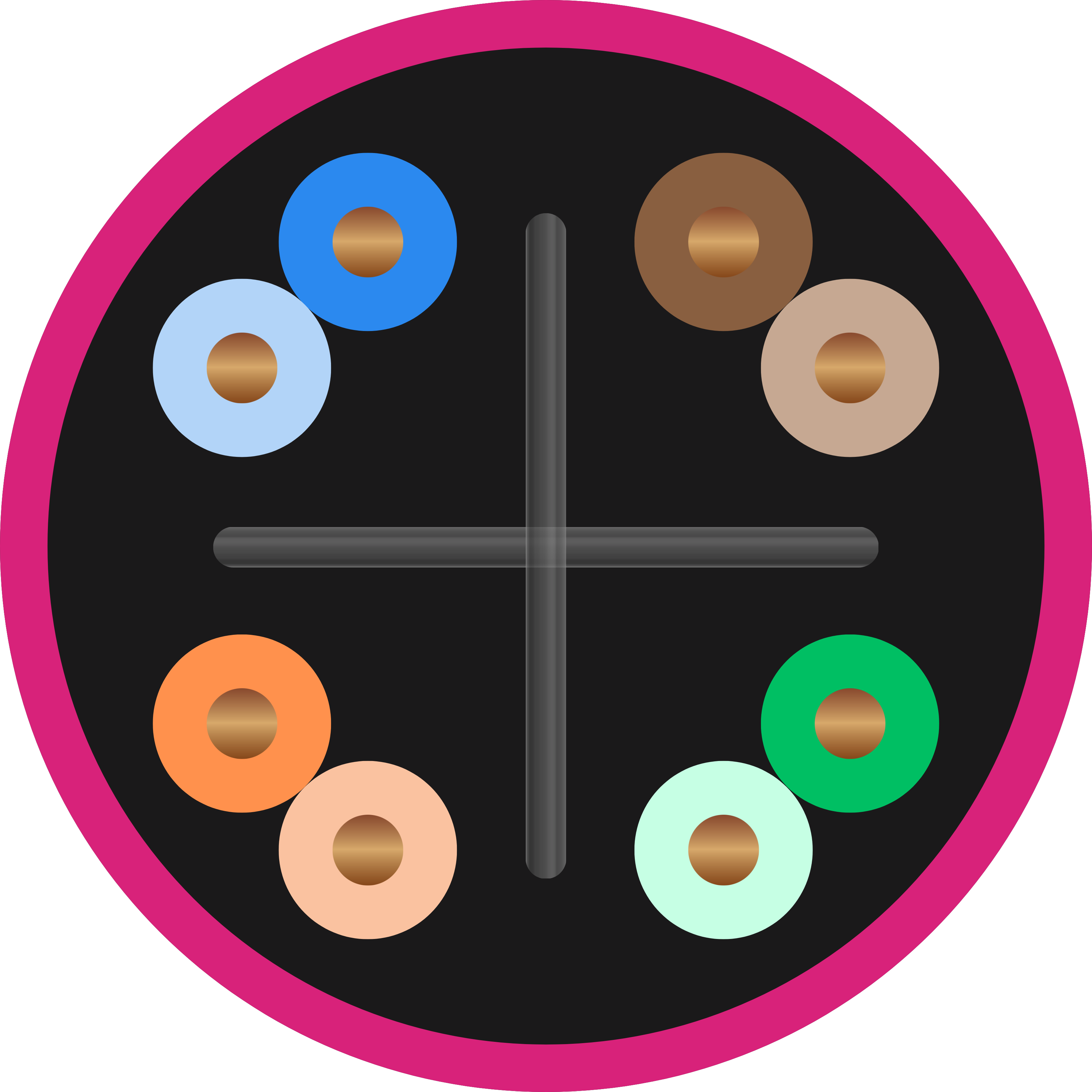

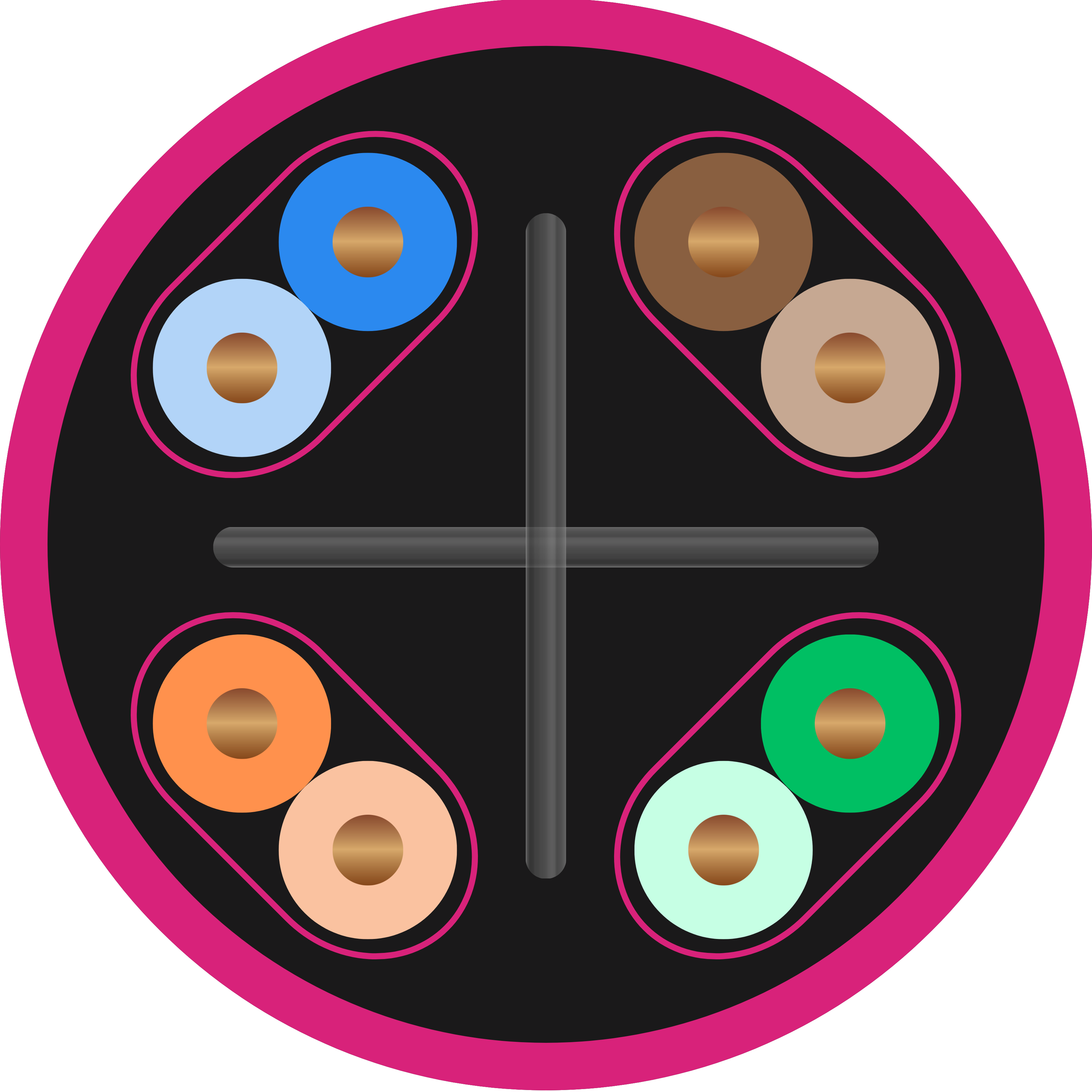

Inside every network cable are smaller copper wires, or ‘conductors’; these conductors are then bundled together and housed in a durable jacket, or ‘sheathe’, which is the visible exterior that you can see when you look at a network cable. The material and arrangement of these internal conductors can also have a big impact on the efficacy of your cabling, and there are a few different types of conductor to consider.

Solid Conductors:

Solid conductors are made from a single, solid piece of pure copper wire that’s housed in the cable’s sheath; these conductors are usually better for long-distance signal transmission as they offer less resistance, and therefore generally suffer less signal loss.

However, because they’re a single, long piece of copper, they’re much more rigid and tend to break more easily; this means that a cable with solid conductors is best used in permanent installations where the cable isn’t likely to be moved much, such as being embedded in walls or ceilings, or in infrequently-disturbed data centres.

Stranded Conductors:

A stranded conductor, on the other hand, is made up of many smaller strands of pure copper wire twisted together. Because it’s not a single, inflexible piece of copper, cables with stranded conductors are usually much more flexible and less likely to break or kink if moved around frequently.

This makes a cable with stranded conductors ideal for scenarios like connecting devices that are often moved or aren’t as structural, such as a laptop or a desktop PC. The downside to this is that, as they’re made up of smaller interwoven copper wiring, a stranded conductor will usually have a higher resistance than a solid conductor, and so can experience slightly more signal loss over longer distances.

Copper-Clad Aluminium Conductors:

A cable with copper-clad aluminium conductors (CCA) is very much as it sounds - instead of the internal conductors being made of pure copper, these cables feature aluminium wire that’s then coated (or ‘clad’) with a thin layer of copper.

The major advantage of these kinds of wires is that they’re both more lightweight and significantly cheaper than the pure-copper alternatives. However, as aluminium features a much lower conductivity rating than copper, a CCA cable will not perform as efficiently as the pure-copper alternatives - both in terms of data speed and signal degradation over longer distances.

Shielded vs Unshielded

To further reduce the interference for network cables, manufacturers can use what’s known as ‘shielding’. This shield can be made from a variety of materials such as copper or a thin aluminium foil, and forms a protective coat around the conductors inside the cable. This coat helps to reduce interference, leading to higher data transmission rates and less signal loss over long distances.

There are a few different ways that a cable can be shielded, but typically a shield is wrapped around each pair of conductors inside the cable. Manufacturers can then shield the cable even further by encasing the entire bundle of multiple conductors inside a larger shield, just underneath the sheath.

You can usually tell whether a cable is shielded or not by the name of the cable itself - the letter before the slash refers to the shielding on the cable itself, while the letters after the slash reveal the shielding for the individual pairs.

U/UTP: Unshielded / Unshielded Twisted Pair, meaning there’s no shielding on either the twisted pair of conductors, or additional shielding under the sheath.

U/FTP: Unshielded / Foiled Twisted Pair, meaning that the cable features a foil sheath around each twisted pair, but no additional shielding other than that.

F/UTP: Foiled / Unshielded Twisted Pair, meaning that the cable has a shield underneath the sheath that encompasses all of the conductors, but no shielding for the individual conductor pairs.

S/FTP: Shielded / Foiled Twisted Pair, meaning that the cable features shielding both around each twisted pair of conductors and underneath the sheath.

Cable Gauge

AWG stands for American Wire Gauge - it’s a standardised way of measuring the thickness of electrical wires. Somewhat counterintuitively, the lower the AWG number, the thicker the cable is - for example, an 18 AWG wire is thicker than a 30 AWG wire.

A thicker cable (the cables with the lower AWG numbers) generally out-perform thinner cables for a few reasons - because they’re thicker they feature a lower resistance, which in turn offers better signal quality, higher data transfer rates, and a reduced risk of overheating. By definition, a thicker wire also tends to be more durable and less damage-prone than a thinner wire, meaning that they can be more suited to more permanent deployments.

If in doubt - the lower the AWG, the thicker the cable, the better the performance!

Sheath Material

Finally, we come to the sheath material; this is - as I’m sure you can imagine - the material that the sheath is made from!

There are a few different codes that can denote the material that makes up the sheath, and different installations can sometimes require specific sheath materials. The sheath’s makeup doesn’t affect the performance of the cable in terms of data transfer rates - ie, how fast the cable can transmit your network data - but it’s an important factor to consider when taking into account where the cable will be placed, the lifespan the cable will need to have, and various fire safety considerations.

Most commonly, cable sheaths are one of the following:

PVC (Polyvinyl Chloride): The most commonly used and inexpensive sheath material. Reasonably durable, flame retardant and water resistant, but not offering any special protection or features.

PE (Polyethylene): Very similar to PVC sheaths but crucially are non-toxic, meaning they can be more frequently used outdoors. PE cables are generally less fire-resistant than PVC cables but have excellent dielectric strength, meaning they can withstand higher voltages before beginning to break down.

LSOH / LSZH (Low Smoke, Zero Halogen): This material is specifically designed to produce the absolute minimum smoke and no halogenated gases when exposed to fire; this makes it a good option for areas with high safety requirements or poor ventilation like buildings, tunnels and ships.

HDPE (High Density Polyethylene): HDPE is a material known for a high level of durability to a wide range of corrosive, abrasive and destructive forces - it’s resistant to most chemicals, solvents and acids, as well as corrosion and water damage, and can continually operate in temperatures down to -60°C. It’s among the more specialist and expensive options and is still not particularly commonly found, but is a great option for critical outdoor applications or installations in corrosive environments.

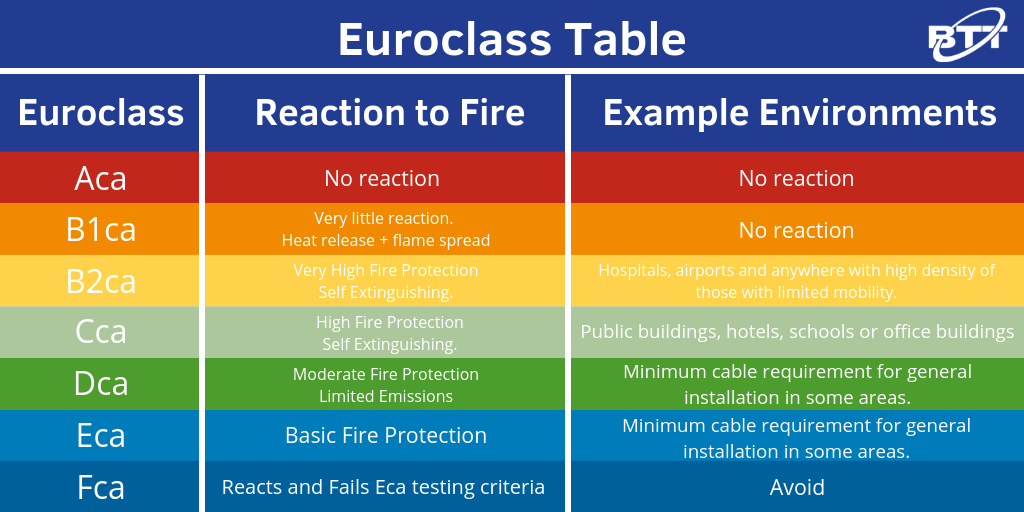

There’s also an additional standard specifically regarding fire safety in data cables, with the catchy name of BS EN 50575; this provides a scale of fire safety for any given cable, gauged by fire spread and heat.

This can range from Basic Reaction (Eca), denoting no particular fire resistance to No Reaction(Aca), meaning that the cable is effectively fire-proof. The standard for most well-known cable manufacturers such as Excel is Dca, or Improved Reaction; however cables will have different designations, so it’s important to make sure it’s the right cable for your needs!

Conclusion

Ultimately, the best cable for your requirements can depend on a number of factors; the maximum data rate you need, the installation location, the types of devices being connected and your project’s budget are all important considerations.

It’s all about balancing speed, cost, and installation requirements; if your network doesn’t need to support high-speed data transfer over long distances, a more affordable option like Cat5E might be plenty for your requirements. However for high-performance networks that need that extra bandwidth, a Cat6A cable with solid conductors and appropriate shielding will be the way to go.

By carefully weighing up your options and requirements, you can keep your network happily humming along for years to come!